Strengthening the Industry 4.0 Workforce through Virtual Reality Training

National Science Foundation Advancing Technological Education (ATE) Impact Report (DUE 2142868)

Project Overview

Strengthening the Industry 4.0 Workforce through Virtual Reality (VR) Training (DUE

2142868) sought to expand opportunities for manufacturing technician education

through development of a VR-based application and curriculum. The project was led by

the Advanced Manufacturing Technical Education Collaborative (AMTEC), an

association of community colleges, technical colleges, and industry partners seeking to

prepare highly skilled maintenance technicians for work in advanced manufacturing. Housed at Owensboro Community & Technical College (OCTC), AMTEC worked closely with zSpace, an industry leader in VR technology, on this project.

Prior to the Industry 4.0 VR project, OCTC and AMTEC utilized National Science Foundation (NSF) Advancing Technological Education (ATE) funding to support and increase enrollment in manufacturing education programs through numerous projects. In 2019-2020, AMTEC—in collaboration with multiple industry leaders—developed a post-secondary trouble-shooting curriculum based on the AMTEC Simulator, a hands-on trainer that introduces students to the fundamentals of real-world integrated systems and components/sub-systems in context with real-world manufacturing. The Industry 4.0 VR project sought to expand access to this unique AMTEC trainer and curriculum through a VR experience.

Why This Project Now?

Artificial intelligence, advanced robotics, automation, analytics, and the Internet of Things are emerging to transform the world of work and are likely to create even

more jobs than they replace.

(Giffi, C., et al. 2018 Deloitte and The Manufacturing Institute Skills Gap and Future of Work Study. The Manufacturing Institute and Deloitte.)

Industry 4.0 VR Project Description

The goals of the Industry 4.0 VR project were:

1) To prepare undergraduate advanced manufacturing students for Industry 4.0

technologies present in the workforce though utilization of VR applications, and

2) To encourage youth to consider manufacturing as a career choice through the

exploration of Industry 4.0 technologies using a VR application.

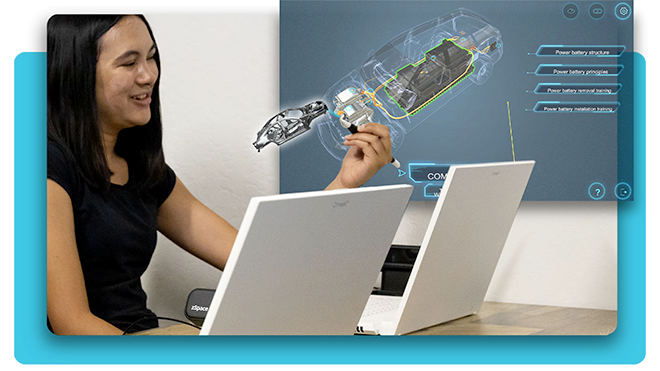

In order to reach these goals, AMTEC collaborated with industry-leader zSpace to create a VR application through which

students could trouble-shoot ten faults on a digital twin of the AMTEC Industry Simulator in a three-dimensional,

computer-generated environment. Once this application was created, AMTEC created two curricula—one in gaming format for

exploration at the secondary level and one for credit-bearing capstone coursework at the post-secondary level—in pursuit of three primary objectives:

1) Engage secondary students in exploring Industry 4.0 advanced manufacturing

concepts,

2) Train postsecondary students to enter the workforce as skilled manufacturing

technicians with a basic understanding of Industry 4.0 technologies and the skills

to apply them successfully, and

3) Provide professional development opportunities to secondary and

postsecondary faculty to increase their aptitude in Industry 4.0 concepts and the

use of VR technology in the classroom.

Strengthening the Industry 4.0 Workforce through Virtual Reality Training focuses on developing multi-skilled technicians with the Industry 4.0 skills needed to increase efficiency and profitability for today’s manufacturers.

Target Population

OCTC’s Industry 4.0 VR project served two primary target populations:

1) Secondary students who may become interested in pursued skilled manufacturing careers, and

2) Post-secondary students currently studying advanced manufacturing.

During the project period:

- 328 secondary students piloted the exploratory curriculum.

- 171 post-secondary students engaged in the capstone curriculum.

- 20 secondary and post-secondary educators attended AMTEC-hosted professional development webinars.

Program Distinctives

Distinctive design elements of Industry 4.0 VR include:

Industry-directed Learning Model

+

–

Subject-matter experts from industry partners across the United States participated in DACUM and Delphi studies which guided

the structure and goals of this project, including the identification of faults to trouble-shoot through VR applications.

Hands-On Learning

+

–

AMTEC’s comprehensive curriculum integrated Industry 4.0

concepts such as robotics, fluid power systems, and the Internet of Things (IoT) within innovative VR applications. This provides students with immersive, hands-on learning experiences to that make complex concepts more engaging and prepare students for real-world challenges in advanced manufacturing.

Collaboration with VR Industry Leader

+

–

This partnership allowed OCTC, AMTEC, and manufacturing leaders to provide subject matter expertise while utilizing zSpace’s technical expertise to create VR applications.

Field Testing with Multiple Partners

+

–

Curricula were field tested with students from over a dozen secondary, post-secondary, and industry partners.

Development of National Certification Exam

+

–

AMTEC convened industry and educational subject matter experts from around the country to create an Industry 4.0 certification exam reflecting real-world industry requirements.

Establishing Revenue-Sharing Model

+

–

To sustain the project beyond the initial grant funding, a revenue-sharing agreement was created between AMTEC and zSpace to

ensure ongoing availability of the curricula.

Key Partners

Partners critical to the success of the project included:

- Manufacturing Employers identified technological needs, including the most relevant knowledge, skills, and abilities required for jobs involving Industry 4.0 automation, IoT, analytics, etc., through DACUM and Delphi studies.

- zSpace provided design expertise in VR to develop needed VR applications for both secondary and post-secondary curricula.

- NOCTI supported creation of a national certification exam.

- AMTEC Partners piloted curricula and provided feedback on efficacy.

- Secondary institutions in Kentucky, Michigan, and Florida explored hands-on, experiential learning curriculum.

- Post-secondary institutions in Kentucky, Washington State, Kansas, and Wisconsin utilized the capstone credit-bearing curriculum.

- Twenty secondary and post-secondary educators attended at least one of three webinars focused on harnessing the power of VR technology to enhance students’ learning outcomes and make education more immersive and captivating through this model.

- Industry partners Boeing, Interactive Trainings Systems, Inc., Toyota, and Toyotetsu North America provided subject matter expertise as part of DACUM and Delphi studies.

Project Impacts

Lasting impacts of the project include:

Industry-Validated Industry 4.0 VR Applications and Curricula

+

–

Embedding VR simulations in industry-validated curricula has the potential to revolutionize how these subjects are taught and strengthens the competency and global competitiveness of the advanced manufacturing workforce.

Development of Innovative Collaboration

+

–

Ongoing knowledge exchange and curricular relevance is fostered by innovative partnerships among educational

institutions, technology leaders, and manufacturing companies.

Sustainable, Adaptable, Forward-Thinking Model

+

–

As new VR applications are created, they can be integrated into the existing curricula, ensuring students continually stay at the forefront of technological advancements and acquire real-world experiences that align with the ever-evolving landscape of advanced manufacturing and Industry 4.0.

Research and Innovation Advancement

+

–

By establishing a foundation for ongoing research in educational technology effectiveness and Industry 4.0 applications, the project drives continuous improvement in technical education.

Faculty Development and Knowledge Transfer

+

–

Professional development for educators enhances their Industry 4.0 expertise and VR teaching capabilities, creating an ongoing cycle of knowledge transfer to future generations of students entering advanced manufacturing.

Encouraging Pursuit of Advanced Manufacturing Education

+

–

Flexible VR learning environments remove traditional barriers to technical education, fostering a more engaging and immersive learning experience and a more robust future Industry 4.0 workforce.

Lessons Learned

Pursue Creative Partnerships

Engage diverse organizations and educational institutions to leverage complementary expertise and broaden project impact.

Prioritize Industry Input

Involved industry stake-holders meaningfully to ensure training aligns with real world needs and expectations.

Design a Financially Sustainable Model

Collaborate with partners to develop products or research with lasting value, generating ongoing revenue to sustain the initiative.

Engage Legal and Internal Teams Early

Consult legal and interdepartmental groups at the outset to streamline contract development and meet compliance requirements efficiently.

Want more information? Contact Jason Simon at Jason.simon@kctcs.edu or 270.686.4616.

Owensboro Community & Technical College © 2025

This material is based upon work supported by the National Science Foundation under Award No. 2142868. Any opinions, findings, and conclusions or recommendations expressed in this material are those of the author(s) and do not necessarily reflect the views of the National Science Foundation.

Learn about our current project, AMTEC Institute for Industry 4.0 Innovation (DUE 2350012) and

how this training can help transform your classroom!