Improving Technician Training in Industry 4.0 Technologies Using Competency-Based Education

National Science Foundation Advancing Technological Education (ATE) Impact Report (DUE 2200761)

Project Overview and Goals

Improving Technician Training in Industry 4.0 Technologies Using Competency-Based Education (DUE 2200761) sought to increase

the number of manufacturing technicians skilled in Industry 4.0 technologies through a flexible, competency-based training program

serving both incumbent and dislocated workers. The project endeavored to remove traditional barriers to technical education for

working-age adults, utilizing non-traditional schedules and fostering a more engaging and immersive learning experience to support the growth of a highly skilled and globally competitive workforce. The program’s innovative structure allowed dislocated workers

who would have otherwise been unable to continue post-secondary education to complete credentialing even after returning to work.

Why This Project Now?

Six out of every 10 manufacturing jobs are unfilled.

(Giffi, C., et al. The Skills Gap in U.S. Manufacturing 2015 and Beyond. The Manufacturing Institute and Deloitte.)

An estimated 2.4 million positions will be unfilled between 2018- 2028, resulting in a potential economic impact of $2.5 trillion.

(Giffi, C., et al. 2018 Deloitte and The Manufacturing Institute Skills Gap and Future of Work Study. The

Manufacturing Institute and Deloitte.)

Recognizing the need of employers for more workers skilled in Industry 4.0 technology and the need of potential workers for non-traditional training opportunities, the goals of the project were two-fold: 1) Prepare the current incumbent and dislocated

workforce to understand and utilize Industry 4.0 technologies, and 2) Encourage manufacturing as a career choice. These goals were addressed through the creation of an accelerated, competency-based learning modality focused on Industry 4.0 skills

called I-TEC (Industrial Technology Enhanced Credentials).

Target Population

OCTC’s I-TEC served primarily two target populations:

1) Incumbent workers employed by local manufacturing companies, and

2) Dislocated manufacturing workers seeking to upskill for reemployment. Incumbent Workers participated in customized trainings tailored specifically for their employer’s needs and desired outcomes. Dislocated Workers participated in college level courses into which competency-based Industry 4.0 skills had been integrated, leading to six stackable college certificates and up to two national certifications.

A total of 126 incumbent and dislocated workers participated in

I-TEC during the grant period.

Program Description

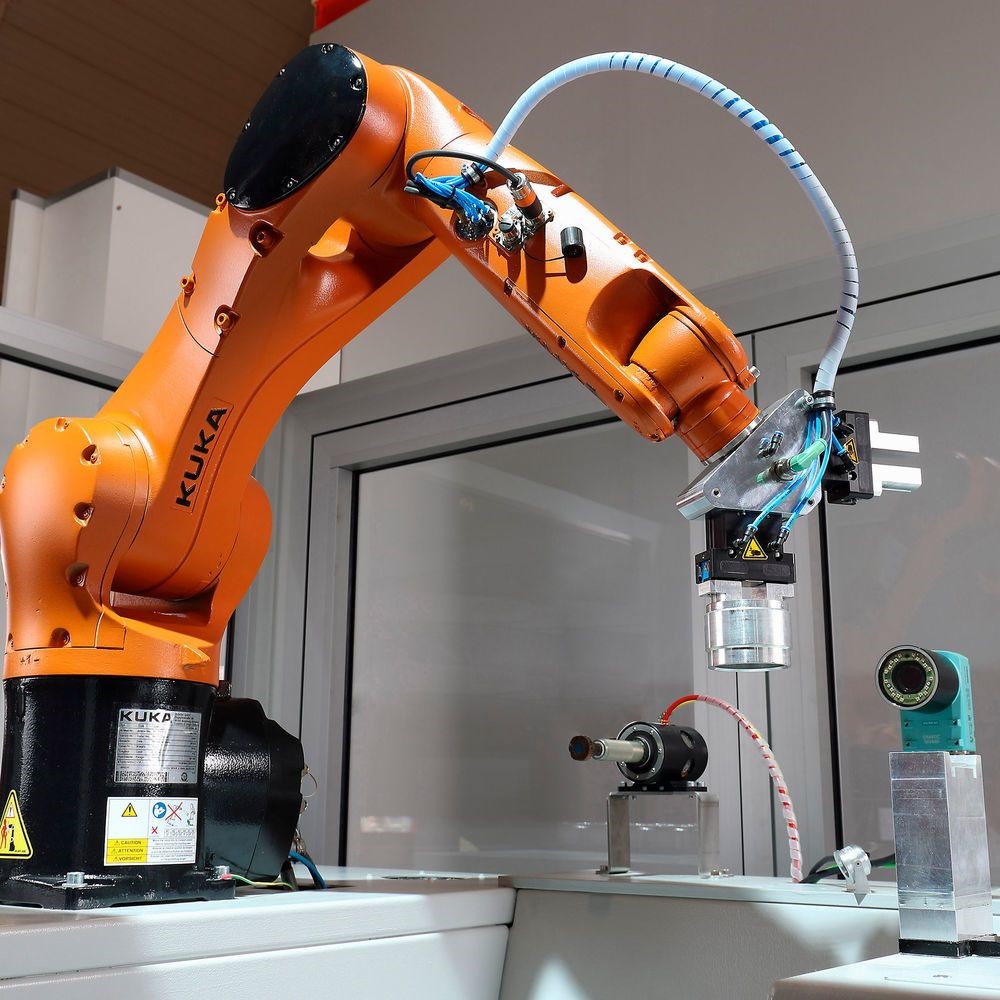

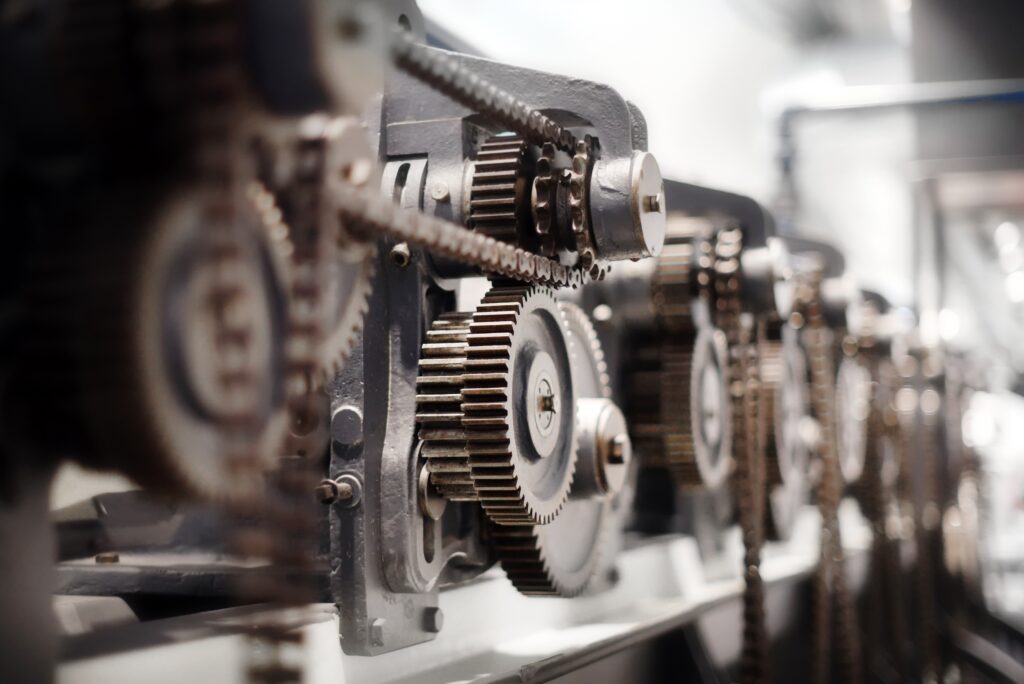

I-TEC embedded Industry 4.0 competencies identified by industry subject matter experts into six of OCTC’s core advanced manufacturing courses: Fluid Power, Maintaining Industrial Equipment, Circuits I, Electrical Motor Controls I, Industrial Robotics and Robotics Maintenance, and Programmable Logic Controllers. In addition, a seventh class, the Industrial Maintenance Technology Capstone, was developed and included as part of the college’s National Science Foundation ATE project Strengthening the Industry 4.0 Workforce Through Virtual Reality Training (DUE 2142868). In addition to comprising these credit-bearing courses, content utilized within the I-TEC program was tailored for incumbent worker training with local employers on a need-by-need basis

Program Distinctives

Industry Focused Learning Model

+

–

Company needs and input directly impacted the structure and goals of this project.

Authentic Assessments

+

–

Rigorous and valid assessments and rubrics, both formative and

summative, were created, mapping to each course competency and requiring demonstration and application of Industry 4.0 skills and knowledge.

Flexible Delivery

+

–

Students schedule appointments to work with instructors in the I-TEC open lab as their schedules allow, building skills and learning core competencies at their own pace.

Competency-based Design

+

–

Hands-on activities provide opportunities to develop and demonstrate skill mastery. Projects, simulations, and assessments evaluate ability to apply concepts using performance-based evaluation.

Stackable Credentials

+

–

Participants who complete I-TEC as OCTC students are awarded six college certificates and can sit for two national certificates.

Wrap-around Coaching Support

+

–

A full-time Employer Liaison/Career Navigator/ Project

Manager provide intrusive advising and personalized students support across a variety of work, life, and academic challenges, including but not limited to college registration, financial aid, and barrier mitigation.

SPOTLIGHT: Paper Company Project

Maintenance supervisors from a facility producing specialty paper needed to enhance the basic electrical skills of their mechanical employees and partnered with OCTC staff to identify key competencies and training outcomes. In collaboration with manufacturing faculty and subject matter experts, OCTC’s I-TEC team designed and implemented a customized electrical training program for

this company, integrating components from the Circuits I CBE course developed through this grant. A total of 63 mechanical employees

participated in five intensive 18-hour training sessions and then underwent an on-site, hands-on assessment at the plant site. All 63 participants successfully completed the course and achieved a 100% pass rate on the hands-on assessment, resulting in all trainees receiving a pay raise.

Key Partners

Partners critical to the success of the project included:

- Employers

- Identified current skill gaps and technological needs, including the most relevant knowledge, skills, and abilities required for jobs involving Industry 4.0 automation, Internet of Things, analytics, etc.

- Validated Industry 4.0 competencies and curriculum, expanding on the DACUM study that participants from Boeing, Toyotetsu North America, and Toyota identified the required duties, tasks, knowledge, skills, traits, and competencies for the Industry 4.0 troubleshooting application to ensure the authenticity of assessments.

- Provided guidance and assisted with the referral of incumbent workers for training through the project.

- Engaged in the design, delivery, and evaluation of the proposed Industry 4.0 competency-based education project.

- Workforce Solutions Trainers and OCTC Faculty assisted in developing and implementing a strategy to meet the grant project goals and reskill current and future manufacturing technicians.

- Kentucky Career Center assisted with referrals of dislocated and underemployed workers for training.

- Green River Area Development District provided funding support for WIOA eligible individuals

Project Impacts

By the end of the project period, the following were accomplished:

I-TEC Curriculum Created and Implemented

+

–

This project brought together industry and college partners to collaboratively address a critical skill need. During the project period, 126 participants increased their skills through I-TEC’s unique, flexible model.

Sustainable – Adaptable Model Developed

+

–

I-TEC’s competency-based flexible and customizable model allowed participants to progress at their own pace while mastering critical, job-ready skills. This model also provided immense opportunity for OCTC to modify format and content to meet specific employer needs.

Braided Funding Utilized

+

–

Eligible employer partners were able to access KCTCS-TRAINS funding, a state-funded program that supports incumbent worker training programs. When approved, KCTCS-TRAINS covered 75% of training costs and employers paid the remaining 25% plus a required 10% KCTCS-TRAINS administrative fee. This ensured the employee/student had no out-of-pocket expenses. Some of the individuals in the I-TEC program received dislocated worker funding, federal financial aid, and Work Ready Kentucky Scholarships.

181 College Certificates, Diplomas, and Degrees Earned

+

–

Among 22 students pursuing college credit through the I-TEC program, a total of 169 certificates and six diplomas were earned during the grant period. Six students have completed all their college coursework and graduated with Associates in Applied Science Degrees in Industrial Maintenance Technology.

SPOTLIGHT: A Dislocated Worker

Ontario came to I-TEC in December 2024 as a dislocated worker. After earning two credentials through I-TEC, he was hired by local manufacturer company in early Spring. Ontario continued with I-TEC once hired and completed the additional required coursework to attain all six OCTC credentials.

Lessons Learned

Pursue Industry Collaboration

Alignment with real-world skill gaps and technological demands is essential to effective

competency-based learning programs.

Prioritize Student and Employer Needs

Rigid academic structures can impede relevance and impact. A displaced worker may need credentials to remain competitive, for example, while an employer might require focused training for technicians without the need for a full degree program.

Remain Flexible

The ability to adapt based on emerging trends is crucial in impacting workforce development in the everchanging manufacturing industry.

Want more information? Contact John Drane at john.drane@kctcs.edu or 270.686.4499.

Owensboro Community & Technical College © 2025

This material is based upon work supported by the National Science Foundation under Award No. 2200761. Any opinions, findings, and conclusions or recommendations expressed in this material are those of the author(s) and do not necessarily reflect the views of the National Science Foundation.

Learn about our current project, AMTEC Institute for Industry 4.0 Innovation (DUE 2350012) and

how this training can help transform your classroom!