AMTEC delivers competency-based, nationally-standardized modularized curriculum. Our content has been fully vetted by our national industry partners.

AMTEC’s Nationally Standardized, Competency-Based Mechatronics Curriculum

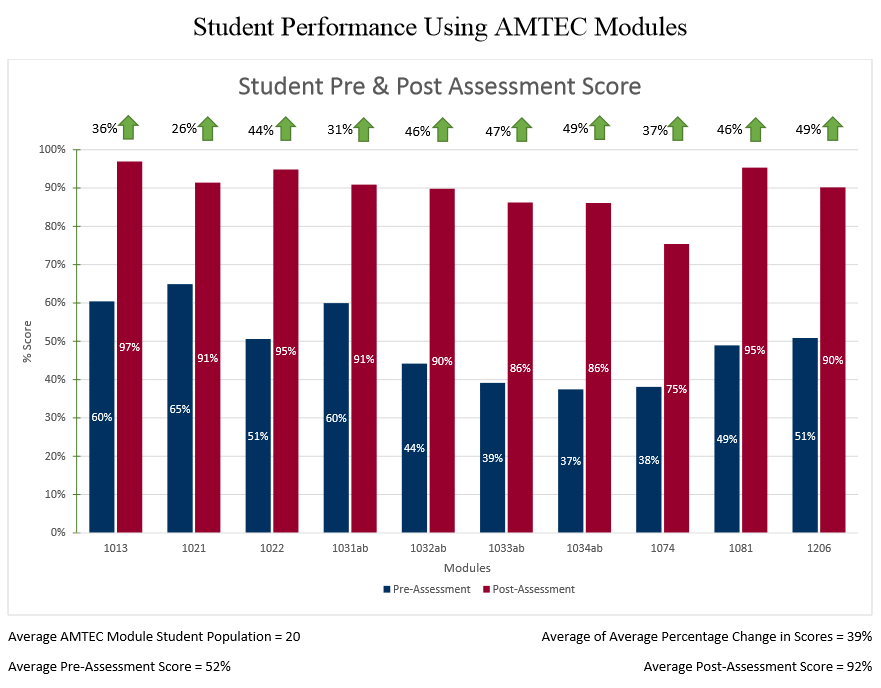

AMTEC offers competency-based, modularized, online curriculum with labs, designed to teach students the technical and critical-thinking skills required to succeed as a multi-skilled maintenance technician in an advanced manufacturing environment. Each module begins with a pre-assessment that allows a student to earn credit for prior knowledge if they can demonstrate mastery and possibly shortens the time required for a student to complete assigned coursework (if allowed by the school utilizing the AMTEC modules.) In addition, these modules include digital lessons, hands-on labs, and assessments. The AMTEC learning management environment allows for instructors to be as hands-on as they want, with features such as adaptive release, online discussion boards, automated grade books and more. When your organization begins using a customized AMTEC learning management system you will also have access to one of the most robust reporting systems available on the web with Intelliboard.

AMT 100: Computer Literacy

+

–

Explains the fundamentals of basic computer literacy as it relates to an industrial environment including basic PC functions and hardware, operating system ins and outs, computer applications and software usage and the use of internet and intranet functionality. Addresses new technologies that are emerging regarding the industrial internet of things.

- AMT 1001 – Orientation to Computer Systems

- AMT 1002 – Operating Systems

- AMT 1003 – Computer Applications

- AMT 1004 – Internet/Intranet

AMT 101: Electrohydraulics/Pneumatics

+

–

Explains the fundamental concepts of fluid power and electro-fluid power systems. Covers the principles of fluid power, calculations of physical properties of fluids and their ability to do work. Introduces the various fluid power components, symbols, circuits. Introduces troubleshooting of fluid power components and systems with an emphasis on safety. Addresses fluids, filters, reservoirs, piping, pumps, actuators, accumulators, control valves, and combination circuits.

- AMT 1011 – Fundamentals of Fluid Power and Electrohydraulics/Pneumatics

- AMT 1012 – Flow, Directional, Pressure Control Valves

- AMT 1013 – Pumps, Actuators, Accumulators

- AMT 1014 – Reservoirs, Fluids, Filters

- AMT 1015 – Hose, Piping, and Tubing

- AMT 1016 – Electrohydraulics/Pneumatics

- AMT 1017 – Systems Troubleshooting

AMT 102: General PM and Predictive Maintenance

+

–

Introduces how routine work is done to keep equipment in good working order and to optimize its efficiency and accuracy. Addresses regular routine cleaning, lubricating, testing, checking for wear and tear and eventually replacing components to avoid breakdown. Introduces students to the various types and styles of predictive and preventive maintenance components, principles, and practices used in industrial applications

- AMT 1021 – Basic PM

- AMT 1022 – Advanced Technologies

AMT 103ab or 103s: PLCs

+

–

Introduces Programmable Logic Controllers (PLC) and elements needed for an automated industrial control system. Introduces memory and project organization within a PLC and provides instruction in basic numbering systems, computer and PLC terminology. Introduces PLC control functions, program structures, language standards, wiring and troubleshooting methods, as well as, real world communications. Requires the student to program a PLC which may include a combination of ladder logic, structured text, sequential function chart and/or function block languages. Includes various protocols of industrial communications used between PLC controlled machines, PLC to PLC, PLC to computer, and computer to computer. All 4 module are available in both Siemens and Allen-Bradley/Rockwell.

- AMT 1031s – Introduction to PLCs (Siemens)

- AMT 1032s – Hardware & Software (Siemens)

- AMT 1033s – Programming PLCs (Siemens)

- AMT 1034s – PLC Communication (Siemens)

- AMT 1031ab – Introduction to PLCs (Allen-Bradley/Rockwell)

- AMT 1032ab – Hardware & Software (Allen-Bradley/Rockwell)

- AMT 1033ab – Programming PLCs (Allen-Bradley/Rockwell)

- AMT 1034ab – PLC Communication (Allen-Bradley/Rockwell)

AMT 104: Blueprint Reading/Schematics

+

–

Introduces the fundamental information in drafting necessary to retrieve read, manipulate and understand a mechanical part print. Instructs students to recognize, identify, describe, and relate the components used in schematics, along with their symbols and connectors, to describe electrical, electronics, pneumatics, hydraulics, and piping circuits, as well as welding and joining symbols interpretation.

- AMT 1041 – Drafting Fundamentals

- AMT 1042 – Orthographic Interpretation

AMT 107: Basic Electricity and Electronics

+

–

Introduces the various elements of basic electricity including the identification of electrical symbols as well as interpretation of schematics, cross-referencing prints, tracing circuits, interpreting sequential function charts, line drawings and time charts. Introduces the student to electrical measurement instruments, including digital and analog multimeters, clamp-on ammeters, megohmeters, and the oscilloscope. Concentrates on control logic components and circuit function. Introduces the student to solid-state devices and applications.

- AMT 1071 – Intro to Basic Electricity

- AMT 1072 – Instruments

- AMT 1073 – Control Circuits & Components

- AMT 1074 – Solid State Devices

AMT 108: Mechanical Drive Systems

+

–

Introduces safety, maintenance techniques and procedures used to maintain industrial equipment, including industrial couplings, chains, sprockets, belts, bearings, shafts, brakes, clutches, gears and cams. Addresses the principles of power transmission, calculations of speed and force and how they affect a power transmission system.

- AMT 1081 – Basic Mechanical Power Systems

- AMT 1082 – Flexible Drives

- AMT 1083 – Couplings and Alignment

- AMT 1084 – Bearings, Shafts, and Seals

- AMT 1085 – Brakes and Clutches

- AMT 1086 – Gears and Cams

AMT 109: Safety

+

–

Introduces OSHA and the OSHA regulations that apply to the auto manufacturing industry. Introduces safety rules and issues in the use of overhead cranes, hoists, rigging equipment, attachment components, calculating sling angle stresses, and safe lifting and turning loads. Provides the knowledge and skills necessary to help sustain life and minimize the consequences of injury or sudden illness to meet the various training needs of those in workplace, school or community settings.

- AMT 1091 – Basic OSHA Safety

- AMT 1092 – Hoists and Cranes

- AMT 1093 – Rigging Awareness & Fundamentals

AMT 110: Welding and Fabrication

+

–

Introduces the power sources used in shielded metal arc welding (SMAW) and gas metal arc welding (GMAW), along with equipment and filler metals used to produce a welded joint. Welding principles will be introduced along with the metallurgy of steel and welding. Introduces shielded metal arc welding safety and shielded metal arc welding processes including flat, horizontal, vertical, and overhead welding techniques. Provides knowledge of theory, safety practices, equipment and techniques required for gas metal arc welding including different transfer methods and position welding. Introduces oxy-fuel welding and cutting, including safety, setup and maintenance of oxy-fuel welding and cutting equipment. Techniques taught in this course include cutting, brazing, and welding.

- AMT 1101 – Introduction to Arc Welding

- AMT 1102 – SMAW/Stick Welding

- AMT 1103 – Welding and Fabrication

- AMT 1104 – Oxy/Fuel Cutting & Joining

AMT 120: Machine Tool Operation

+

–

Introduces machining operations, procedures and machines used by multi-skilled industrial maintenance technicians. Introduces the safe and correct operation of lathes, milling machines, drill presses, metal saws and hand and power tools. Students will work with various measuring and layout tools found in industrial environments.

- AMT 1201 – Intro to Machining Operations

- AMT 1202 – Turning

- AMT 1203 – Milling

- AMT 1204 – Drill Press

- AMT 1205 – Saws

- AMT 1206 – Hand and Power Tools

- AMT 1207 – Measuring and Layout Tools

AMT 105: Robot Maintenance

+

–

Introduces robotics in regard to industrial robotic safety standards, applications, types of classes for industrial robots, basic system components, robotic motion concepts, key programming techniques, definitions and the common terms associated with computer integrated manufacturing (CIM) as it relates to robotic cells. Instructs students on the mastering concepts of preventive maintenance techniques required for a robot and their backup systems in addition to recovery procedures needed to interpret robot error codes and perform a safe recovery start up procedure on robotics equipment, as well as integrating robotic applications in a PLC-controlled, automated system.

- AMT 1051 – Introduction to Robotics

- AMT 1052 – Programming/Editing Robots

- AMT 1053 – Robot Maintenance and PM

- AMT 1054 – Error Codes & Troubleshooting

- AMT 1055 – Integration of PLCs & Robots

AMT 106: Controls and Instrumentation

+

–

Covers the diversity of control devices including: theory of operation, applications in automation control and troubleshooting and repair. Introduces identification, installation, replacement, and troubleshooting of automation controller circuit boards and modules. This course also introduces the installation, maintenance and troubleshooting of common input devices. Methods of motor controls including on-off, proportional, integral, and derivative including PID loop tuning and quality are discussed. Automation output devices including AC, DC, and servo motors, variable speed drives, relays, motor starters and sizing of components for various applications is also covered.

- AMT 1061 – Fundamentals

- AMT 1062 –Sensors and Photoeyes

- AMT 1063 – Calibration and Loop Training

- AMT 1064 – Final Control Elements

Students will self-register within their individual colleges AMTEC Learning Management System (LMS) and access their courses as approved by their instructors. View the General Maintenance Mechatronics Curriculum Overview here.