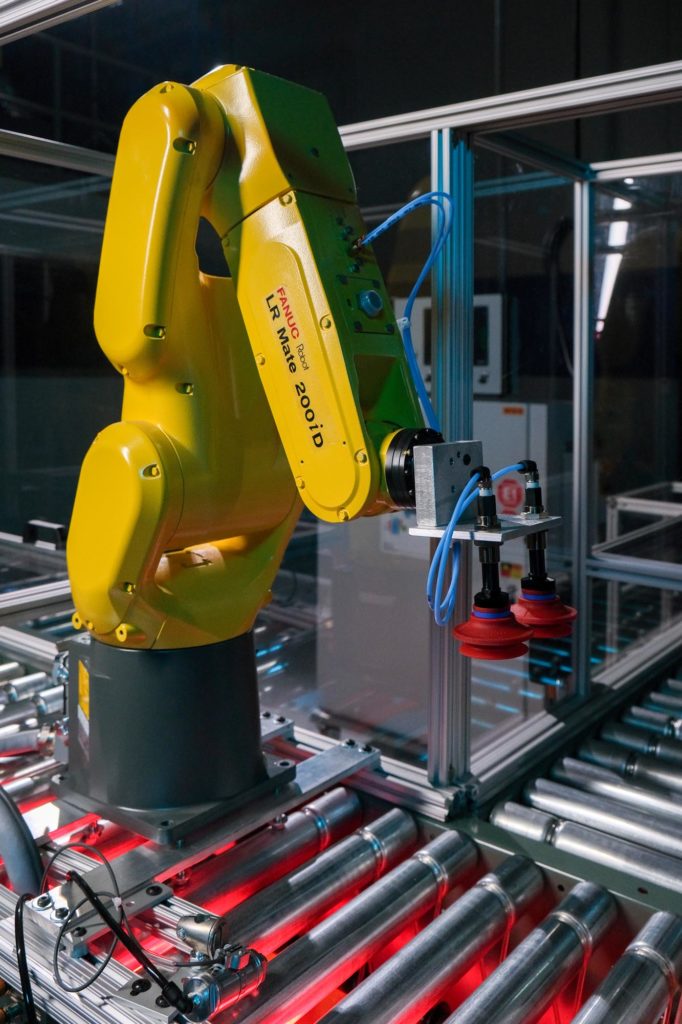

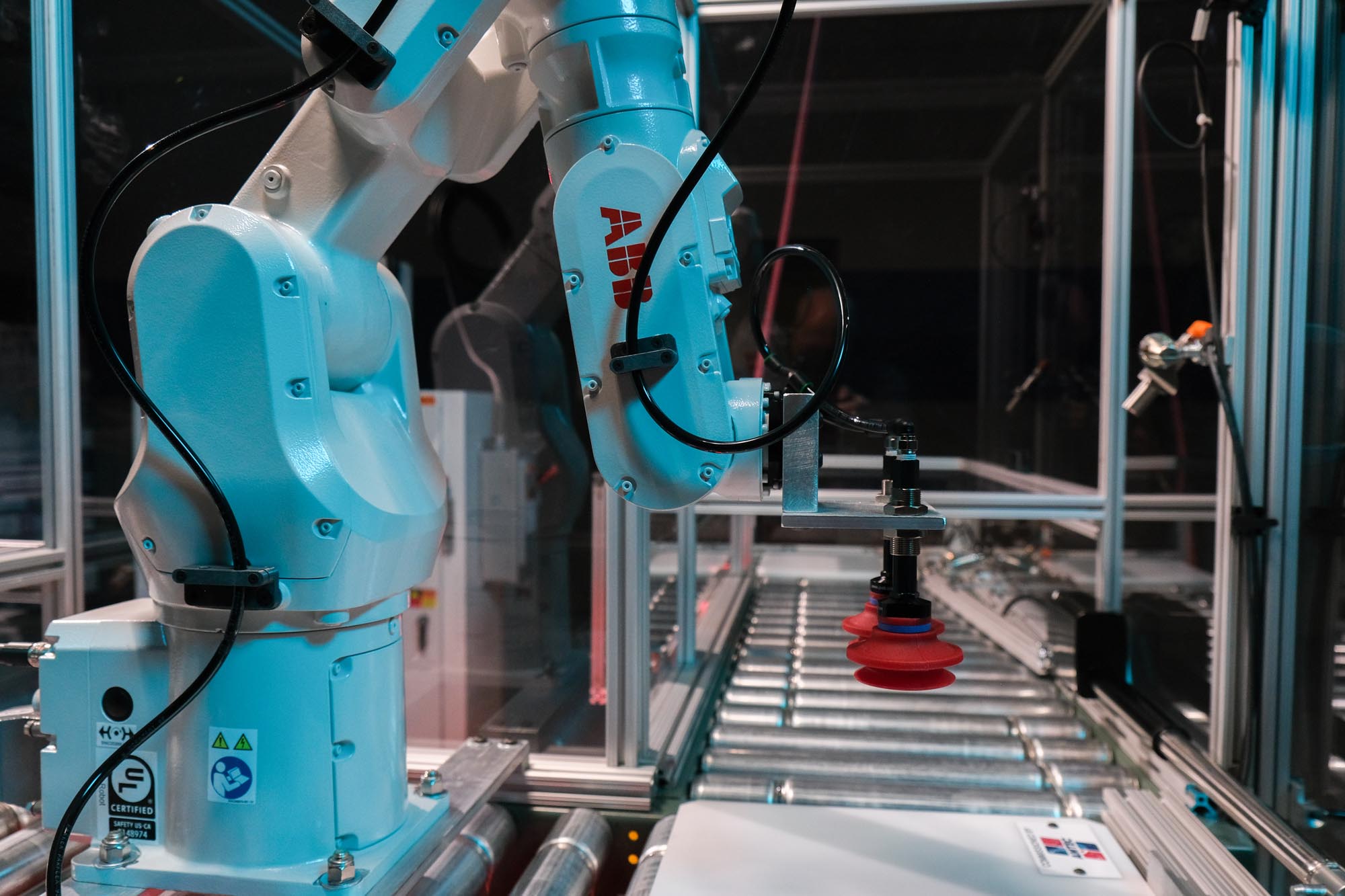

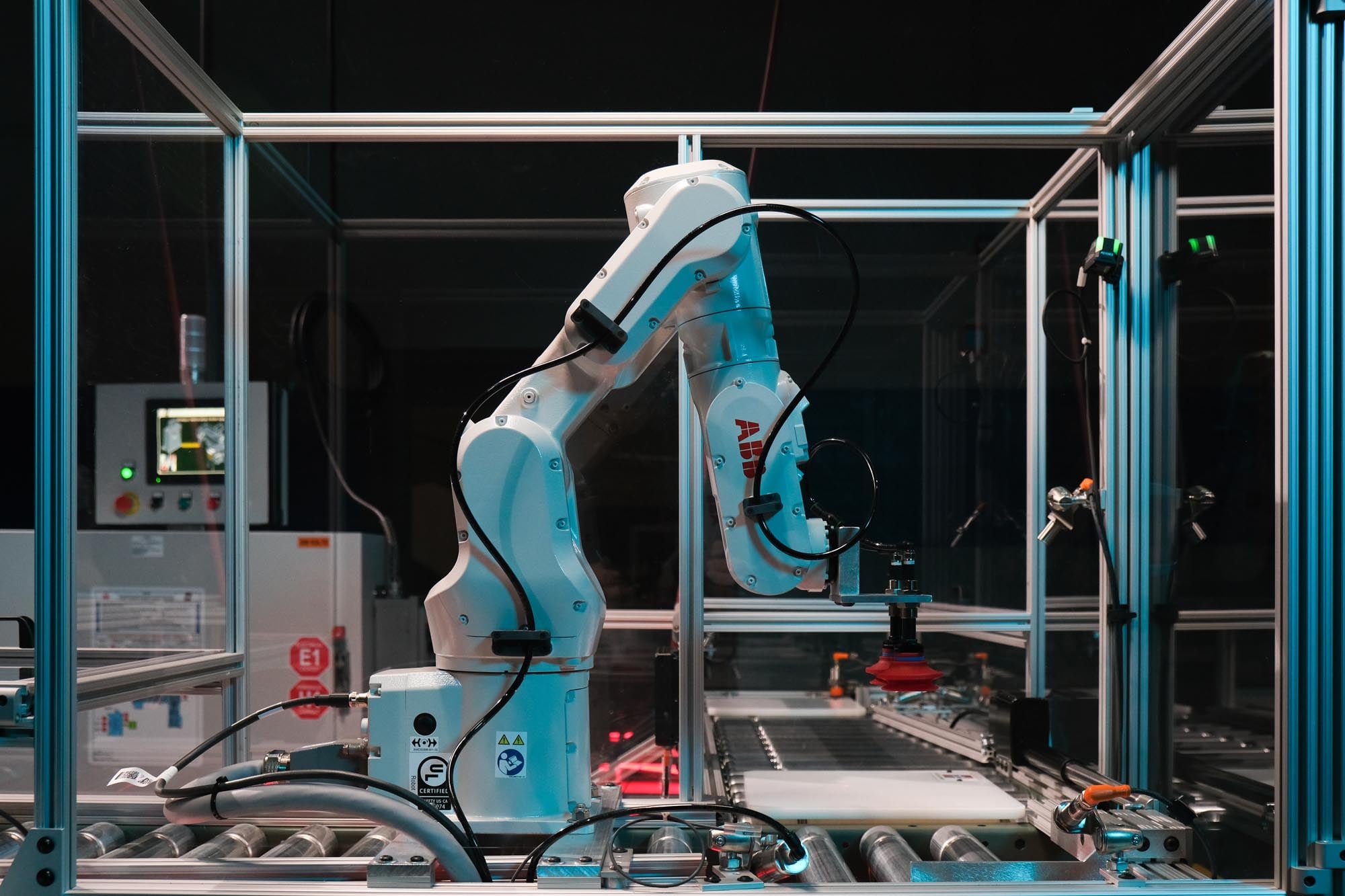

- Introduces the fundamentals of real-world integrated systems such as safety, robotics, pneumatics, hydraulics, and lubrication.

- Provides components with sub-systems in context with real-world manufacturing. Examples: variable frequency drives, human-machine interface and controls, safety circuits, and process logic controller.

- It provides an almost limitless and increasingly complex system “soak time” to develop a mastery level of understanding of a complete integrated manufacturing system. Areas include machine services, safety devices, robotic controllers, system faults, and electrical controls.

AMTEC Manufacturing System Simulator Technical Data Sheets

AMTEC Manufacturing System Simulator

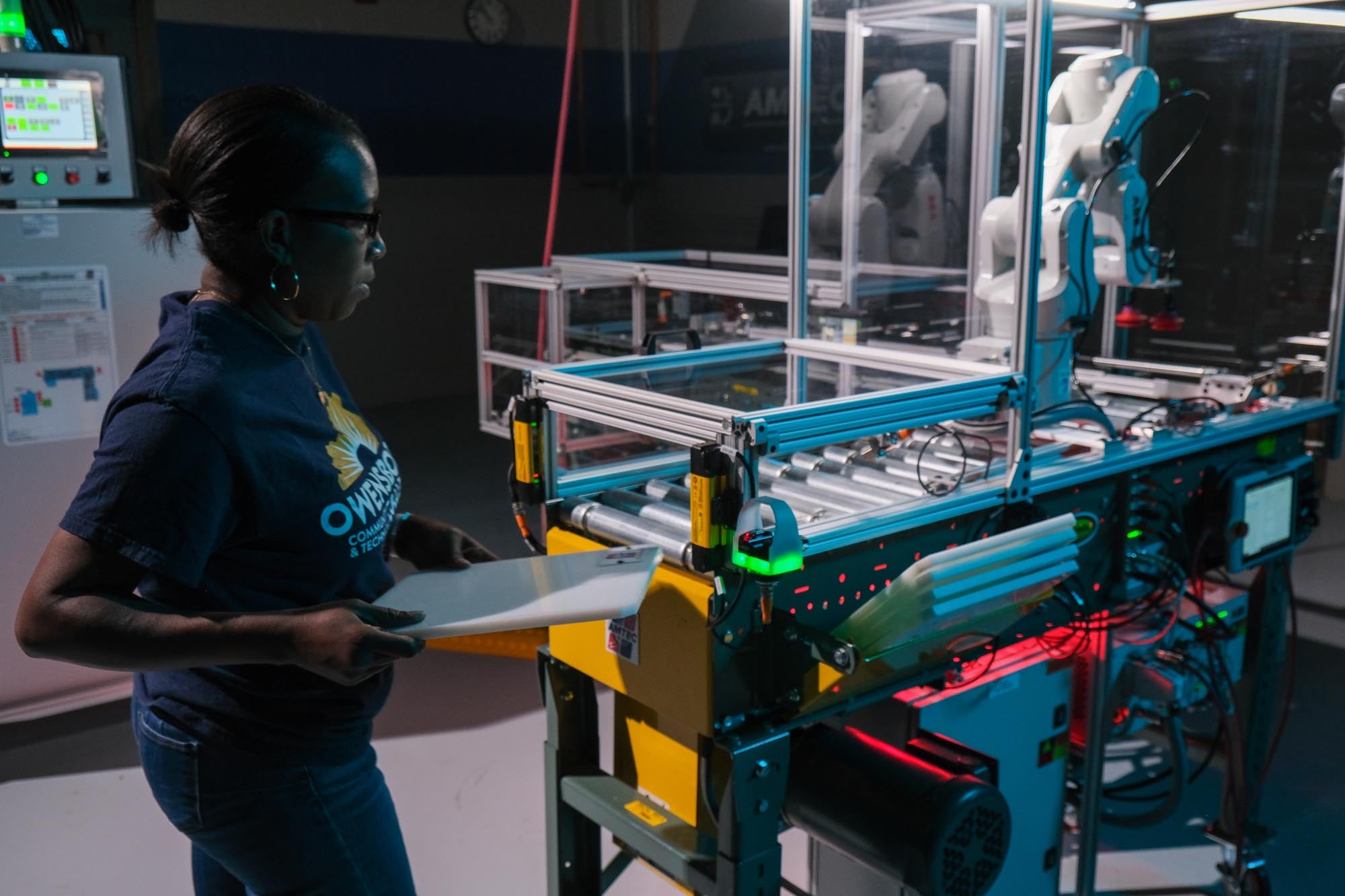

The AMTEC Manufacturing System Simulator V2 was designed and built with flexibility and variety in mind. This machine can be used to provide a platform for troubleshooting and safety training as well as reinforcing basic principles learned in a classroom environment. It was specifically designed to support the AMTEC curriculum.

The AMTEC Manufacturing System Simulator:

- Allen Bradley Programmable Logic Controls

- Siemens Programmable Logic Controls

- Or both

The Simulator will support technical training at a variety of institutions including schools and companies. It is a viable platform for “Lean Manufacturing” training. It is adaptable to local needs and is transportable. Relevant training is easily matched to the Simulator.

The features and functionality of the AMTEC Integrated Manufacturing System Simulator are demonstrated through a video posted below: